- Compressed air system

- HVAC System

- Spare Parts

- Rental

- Services

- Contract Air

- Design & Installation Service

- SUTO-iTEC Measuring Equipment

- News

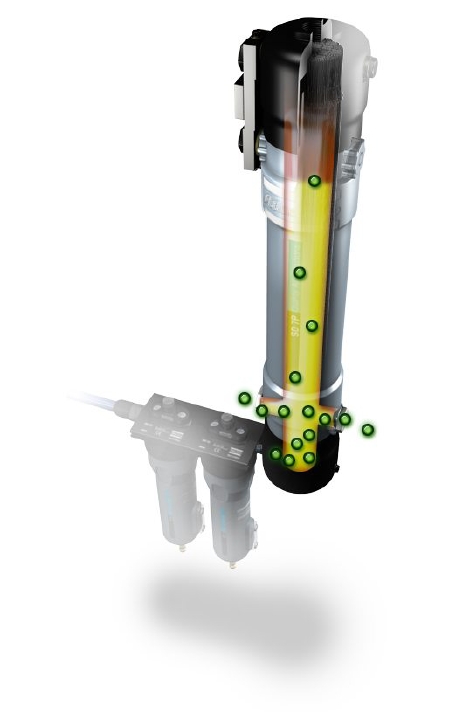

Membrane

SD membrane dryers with pre-filters remove oil, particles and moisture from compressed air in the most demanding conditions. They ensure the lowest pressure drop and purge air loss for the highest possible efficiency – saving you time and money through your production process. From small spaces to environments with fluctuating ambient temperatures, SD dryers can perform in a wide variety of harsh and critical conditions. Two models are available, each with a range of performance, to offer you the exact air treatment you require.

SD: Membrane dryers

Customer benefits

- Versatility - SD dryers perform in all sorts of areas: small spaces, areas where flexible mounting is require, high vibration areas and in widely fluctuating temperatures.

- Safety assurance - SD dryers provide dry air in environments with strict safety or environmental requirements. These include low flow environments, areas without an electrical supply, explosion-proof facilities, noise-sensitive and corrosion-sensitive areas.

- Clean and dry air for critical applications - Because they are not powered by electricity, SD dryers function safely in environments that must be explosion proof, suchaslaboratories. Thanks to their quiet operationthey can be used close to the work place.

- Optimal efficiency – SD membrane dryers contain thousands of hollow fibers with an innovative inner coating. Compared to conventional membrane dryers, this unique coating increases the separation efficiency between water vapor and oxygen and nitrogen, giving an unprecedented low air leakage and the lowest purge air loss.

- Flexibility in choice – SD dryers are available in two models, each with a different Pressure Dew Point Suppression. This choice of performance ensures that, regardless of your production environment and demands, there is an SD dryer to meet your needs.

- Energy savings – Due to the straightforward design of the SD dryer, compressed air has no twists and turns to make inside the housing. This leads to minimal pressure drop and utmost efficiency throughout the drying process.

-

Technical data

Technical Specifications Capacity FAD (l/s) 1.5 - 55 l/s Capacity FAD (m³/h, cfm) 5.4 - 198 m³/h Working pressure 7 - 13 bar(e) Product Review

Other products in category

.jpg)

Refrigerant

Dry, quality air is vital for long-term, trouble free operation of your processes. Atlas Copco’s FX dryers protect your products and systems against...

.jpg)

Heatless desiccant

CD heatless desiccant air dryers are designed for a long lifetime of reliable operation. Using only compressed air as a purge, they provide you with...

.jpg)

High Pressure

Atlas Copco’s HFD air dryers remove the water remaining in compressed air after its passage through the compressor after-cooler. They are designed for...

.jpg)

.jpg)

.jpg)